HMT MACHINE TOOLS LTD

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to HMT MACHINE TOOLS LTD

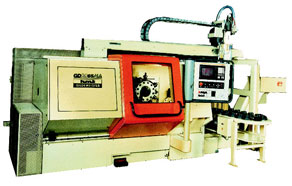

Grinding Center

Unique - Complete Grinding in one set-up

» Hardened and ground wheel spindle mounted on high precision antifriction bearings.

» Work head spindle supported on super precision taper roller bearings.

» 3-Axes CNC Grinder with multi-station hydraulically indexable turret for multi operation facilities - external, internal and face grinding - in single chucking with all the three wheels driven by a common motor.

» Hydraulically operated swing type auto dresser for OD, ID, and face grinding wheels by a common dresser.

» Suitable for automobile components such as gears, bearing cups, bushes and other components used in general engineering and strategic sectors.

» Ideal for flexible production.

» Significant reduction of non-productive time due to single loading/unloading cycle.

» Lower cost with faster throughput, reduced part handling and inprocess inventory.

» User-friendly grinding cycles customised screens (picto programming).

» Higher quality and shortening of cycle time due to one time clamping.

» Pre-streteched directly driven ballscrews with AC digital servomotors for linear axes.

» Auto dressing of all the wheels by a common dresser.

Special Executions :

» High Frequency internal grinding spindles.

» Hydraulic chucking devices.

» MARPOSS inprocess gauging.

» Dynamic wheel balancer.

» Air gap & crash controller.

» Linear scale for axes.

» CBN Grinding facility.

» Fully tooled up solutions.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.